Resistance – even under extreme conditions.

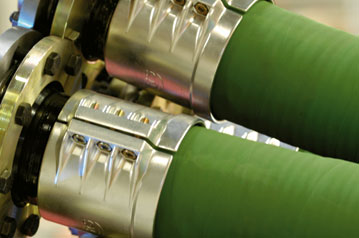

HANSA-FLEX industrial hoses for maritime applications offer excellent material resistance and a wide product range.

As a system partner, HANSA-FLEX offers a complete range of hose lines for ships, drilling platforms, power stations, wind parks and other offshore facilities. Because everything comes from a single source, there is no division of responsibility, no complex interfaces, greater budgeting reliability and optimum availability. Our years of collaboration with dockyards and shipping companies have brought us extensive expertise in industrial hoses for use in marine applications. This results in robust products that are designed to withstand the most extreme conditions and guarantee the necessary safety for people and the environment.

Cooling water, air and chemicals can be transported just as reliably as fuel or lubricating oil. The hoses offer exceptional resistance to seawater, vibrations, temperature influences, ozone and abrasive media. PTFE corrugated hoses are particularly impressive – as well as the properties already mentioned, they are non-flammable and maintain their internal diameter without kinking even when used in a constricted radius. They represent a perfect space-saving solution for ships. Custom designs are also available that break galvanic currents and thus prevent metal corrosion.

Quality assurance

HANSA-FLEX offshore industrial hoses are subject to stringent quality standards. We know that they are components that affect safety. We regular audit our upstream suppliers and consistently assure the quality of our products using thorough tests.

Advice and engineering

HANSA-FLEX supplies complete solutions, tailored to individual applications from start to finish. Our years of experience in marine applications mean that we can offer expert advice at all phases of a new development project. Engineering includes transfer of know-how, production of prototypes, optimisation of components for series production, performance of tests and approval procedures and detailed documentation.

Genuine spare parts with X-CODE

All hose lines are assigned an X-CODE, which is engraved directly on the fittings. This ensures that an identical spare part can be ordered and delivered when required. This reduces unscheduled stoppages to a minimum. The use of genuine spare parts also rules out the risk of fitting components from other manufacturers that may not exactly meet the specifications.

At home on all the world’s oceans

HANSA-FLEX Industrial Hoses – Offshore

- All maritime applications

- For transporting water, air, chemicals, fuels, lubricating oils and other fluids

- Complete range of nominal diameters from 25 to 200

- Excellent resistance to seawater, abrasive media, ozone and vibrations

- Flame resistant

- Variety of connection options

- Tailored solutions

- Advice at all project phases

- Performance of all tests and approval procedures

- Technical documentation

- Employee training

- X-CODE for reliable identification when replacing

- Genuine spare parts